Idea: 3D-Printed Sheilding

Hi All,

I am quite interested by this project. If shielding has not yet been implemented, why not use conductive filament to 3D-Print shielding plate for the circuit.

The filament, would have to take some heat, so it would seem that conductive ABS would be better than the PLA.

Perhaps even, the 3D print could also be coated with high-copper content conductive paint, to give it just a little more RF shielding mojo.

If there is interest, perhaps I could help, I have Rhino 3D, and am pretty handy with it.

I suppose that making an open-source CNC model would help too.

Take Care, BrendaEM

Hi BrendaEM,

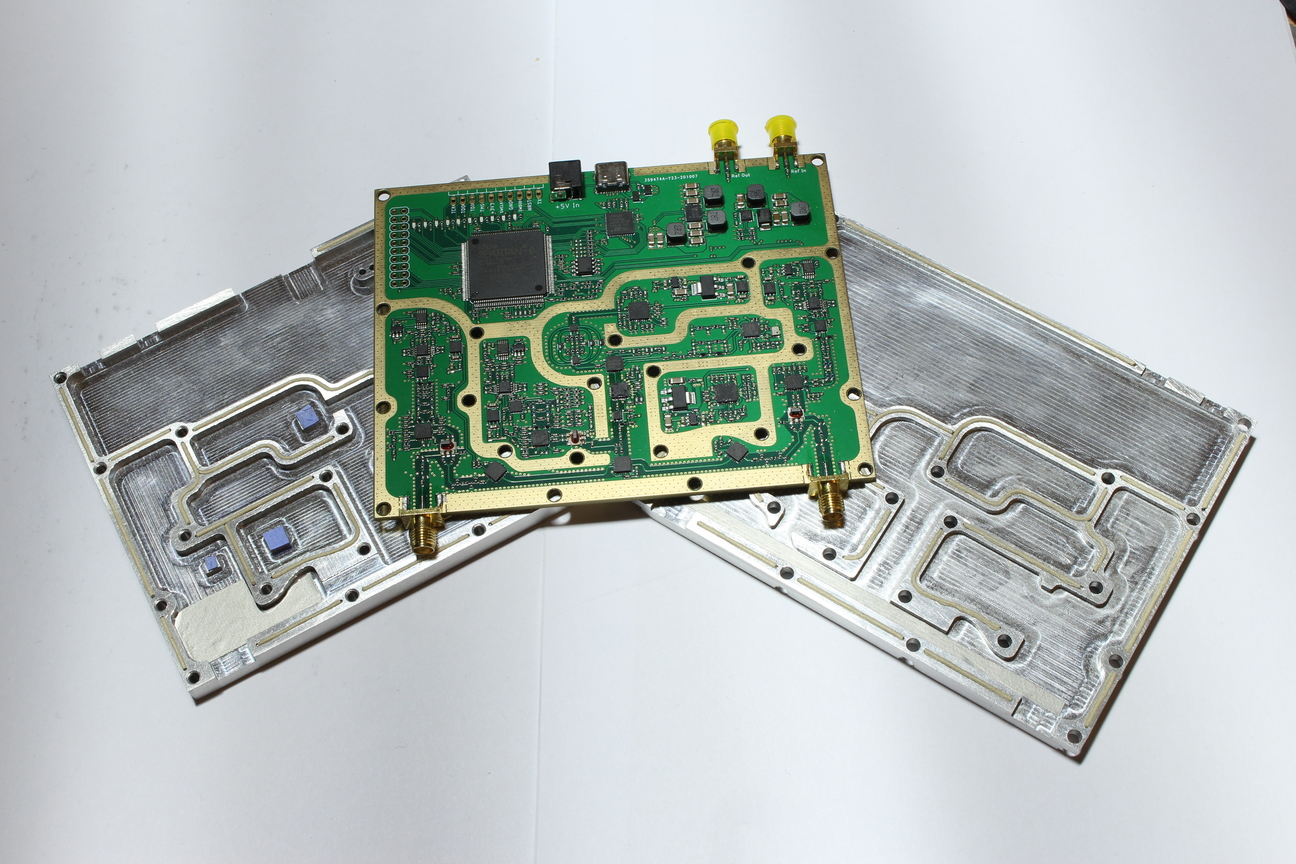

shielding has already been implemented in the form of an aluminum housing (shown here with additional modifications which turned out to be unnecessary):

The files for both sides of the housing are also in the repository (Hardware/TopShield.step and Hardware/BottomShield.step). If you attempt to 3D-print them, I would be very interested in the result and especially how good conductive filament would work for shielding.

Hello.

Was shielding effectiveness measured using any method at all? I'm also interested in testing some 3D-printing conductive materials for shielding, and if we had guidelines to measure and compare it would be good to work on it.

Em ter., 12 de out. de 2021 às 12:42, jankae @.***> escreveu:

Hi BrendaEM,

shielding has already been implemented in the form of an aluminum housing (shown here with additional modifications which turned out to be unnecessary): [image: grafik] https://user-images.githubusercontent.com/16818866/136987028-cda34883-4da7-43a4-9277-d1dac234262a.png

The files for both sides of the housing are also in the repository (Hardware/TopShield.step and Hardware/BottomShield.step). If you attempt to 3D-print them, I would be very interested in the result and especially how good conductive filament would work for shielding.

— You are receiving this because you are subscribed to this thread. Reply to this email directly, view it on GitHub https://github.com/jankae/LibreVNA/issues/51#issuecomment-941133471, or unsubscribe https://github.com/notifications/unsubscribe-auth/ALXBFIETUNSCWIJU4ICOE6LUGRJNNANCNFSM5FZRBIDA . Triage notifications on the go with GitHub Mobile for iOS https://apps.apple.com/app/apple-store/id1477376905?ct=notification-email&mt=8&pt=524675 or Android https://play.google.com/store/apps/details?id=com.github.android&referrer=utm_campaign%3Dnotification-email%26utm_medium%3Demail%26utm_source%3Dgithub.

The only thing I compared was the dynamic range (or rather: the signal leakage between the ports) with and without shielding. You could attempt the same thing with a 3D-printed shield and compare it to a measurement with an aluminum shield. But I believe most of the remaining signal leakage is actually through the PCB/components and not through the shield (various attempts to improve the shielding like the RF gaskets in the picture above did not make any difference)

In case the printed shielding is not that good, there is another option. To print with regular plastic and then apply a copper-based conductive coating. There are spray paints specifically for this purpose. I would be very interested in either results.